Technology

Batoco combines Formula 1 helmet carbon fibre with shock-absorbing foam and heavy lab-testing to provide highly protective shin pads.

Learn more about the energy absorbing mechanism in the below video.

INNOVATIVE CARBON COMPOSITES PROCESSING

High strength, high stiffness carbon fibre used in Formula 1 helmets and the aerospace industry composes the outer shell of your custom shin guards.

This is important because all carbons are not equal! Some offer more stiffness while others are more flexible; some break easily while others are tougher etc.

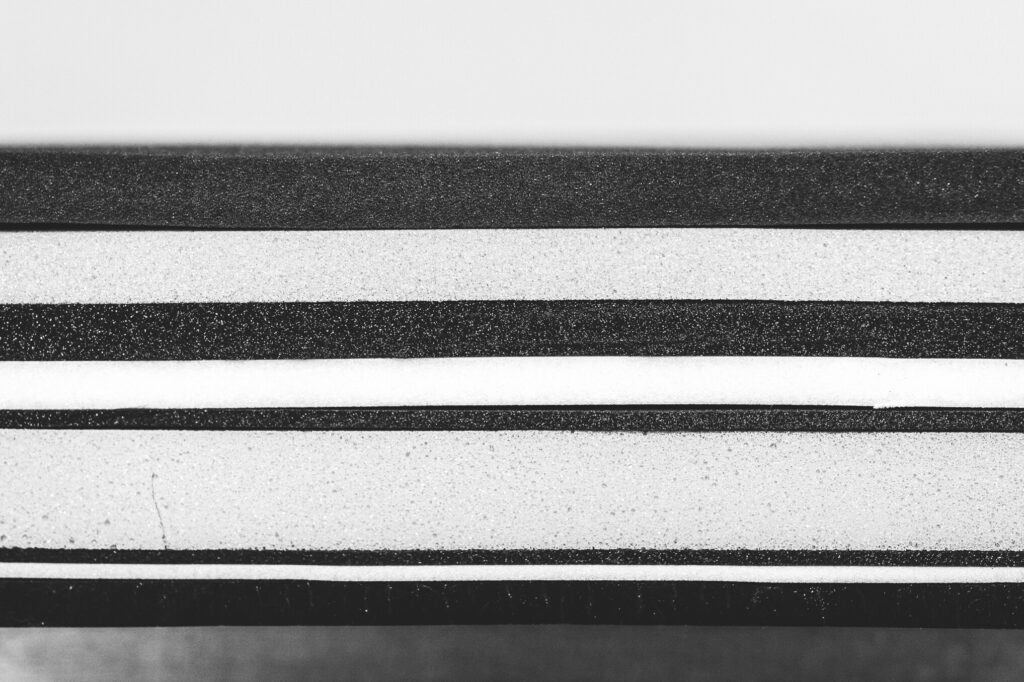

The engineering team carefully selects its carbon yarns, decides how the yarns are combined to create a specific fabric structure and chooses resin formulations good at impact absorption. The fabrics and resin are then combined into a material called “prepreg”.

Prepregs offer the benefit of a predetermined fibre-resin ratio, which impacts the strength-to-weight properties of the final part. Lower-end materials do not enable to accurately obtain a specific fibre-resin ratio.

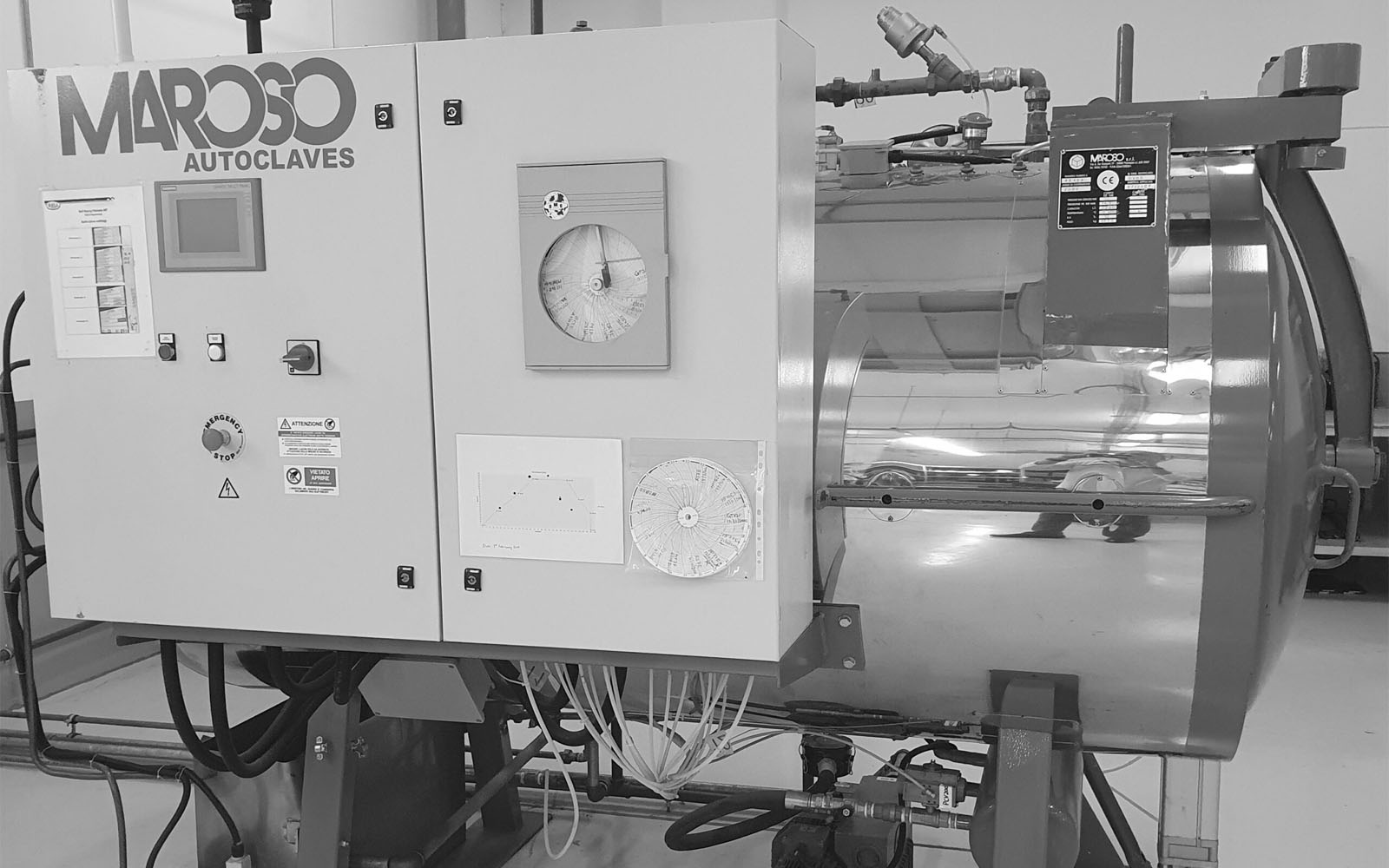

Several composites, each with their own strengths, are then combined to obtain your leg specific shell. Batoco uses custom high-heat, high-pressure machines to compress and harden the composites into your final shell. The curing phase is critical to the bonding of the various layers and obtaining protection properties unachieved by lower end processing methods.

PorFox FOAM AGAINST ALL IMPACTS

Why would you wear shin guards that protect but are uncomfortable?

What if you could have the best of both worlds?

Batoco has worked with a renowned university to develop PorFox foam. The foam provides safety, comfort and ease of movement. On metal stud, shoe or leg impacts, the foam hardens and absorbs additional energy, then relaxes again. PorFox therefore enables thin and close to the body shin guards.

PorFox components pass the REACH standard, which makes its manufacture comply with the most advanced eco-responsible regulations. Non-toxic, latex-free and hypoallergenic properties make PorFox suitable for direct skin contact. The closed-cells of PorFox avoid moisture absorption and with it, possible rapid degradation of the foam properties.

Nevertheless, the dynamic properties of foam change at different temperatures. A perfect foam for summer conditions might be too firm for a snowy boxing day game and therefore not help protect your leg. This is why Batoco consistently tests new foam formulas and looks into your specific playing environment to provide you with the most adapted backing

- PorFox 50%

- Competitors 88%

- 72%

- 100%

- 79%

Transmitted energy ratio for a range of impact forces and impactors (stud & flat plate)

Beyond safety standards

Football shin pad safety standards (EU, US) mainly protect against lacerations and minor impacts. However, many of your discomforts and injuries are directly caused by a collision with other players. These contacts are certainly not going away.

What if your shin guards could help you stay in top shape?

Going beyond the current standard requirements, Batoco developed its own test rig in collaboration with a renowned university to simulate player contacts that take place on the pitch. A series of strain gauges and accelerometers capture the energy transmitted to a leg-shaped anvil, enabling a detailed analysis of impact.

The test rig enables to change various parameters that affect lower leg bone fractures. Impact force, angle of collision, impactor shape, impact location and impacted leg shape can all be changed to deeply test protective properties of Batoco’s shin guards.

Hundreds of pairs have been tortured on the test machine, and Batoco learned from each test to provide you with the best protection while respecting your constraints.